PROFISPOT-TF® Multipoint Free overhead Arm Table Spot Welding Machine

Manual table spot welding machine with free overhead arm with X-Y coordinates

The X-Y coordinate Crank-arm Manual Mobile Spot Welding Machine with Flat Table uses principle of robotic arm.

Multiple elbow robotic arm adopts manual mobile mode to be moved to welding position as per welding requirement. The machine is of easy operation, convenient and flexible to use.

The welding characteristic is that it adopts double-side single point welding mode, with full flat table as lower welding electrode.

It is applicable for welding multiple-point product on flat surface.

It can effectively guarantee smooth welding on product surface and consistency of welding spots.

According to your requirement: the max welding thickness is 4mm+4mm. 120KVA power source is recommended.

The flat table size is2000 x1200mm.

Resistance welding machine with copper table and balanced welding head, “zero weight”.

Highest flexibility, available for welding galvanized materials, normal steel, stainless steel and aluminium.

Different working areas are available upon request.

This Table-Roof welding machine are the best choice for metal door manufacturers and perfect for sealing horizontal and vertical surfaces due to their simplicity, reliability, being easy to operate and at the same time highly efficient and multifunctional.

Welding machines with copper table, welding head balanced and easy to handle. Great flexibility with solutions for steel, galvanized steel, aluminium. Conventional generators Medium Frequency (1000 Hz). Actuators da45 1800 daN.

The first prototype of the Roof type spot welding Machine was developed to meet the needs of a worldwide customer. The mission was to weld pieces heavy and thick in a fixed position. The solution has been, is and will be the series table Roof, which in fact meets these expectations thanks to the easy handling of the welding head positioned above the work pieces, staking them exactly where required. Easy set-up, to use, maximum flexibility and versatility: targets achieved.

Possibility to choose between different models (for example, one head, two heads, X vertical gun, G vertical gun, different sizes, different powers, quality control, etc. …) which meet the specific needs of the end user.

Constant control of the current, active on every part of the copper bench, by means of a toroid belt, controlled by a Medium Frequency system (Inverter).

Advantages:

- Refined welding

- No need for special equipment

- Maximally easy working area access

- Production flexibility

- Reduced labor costs

- Horizontal and vertical surface welding

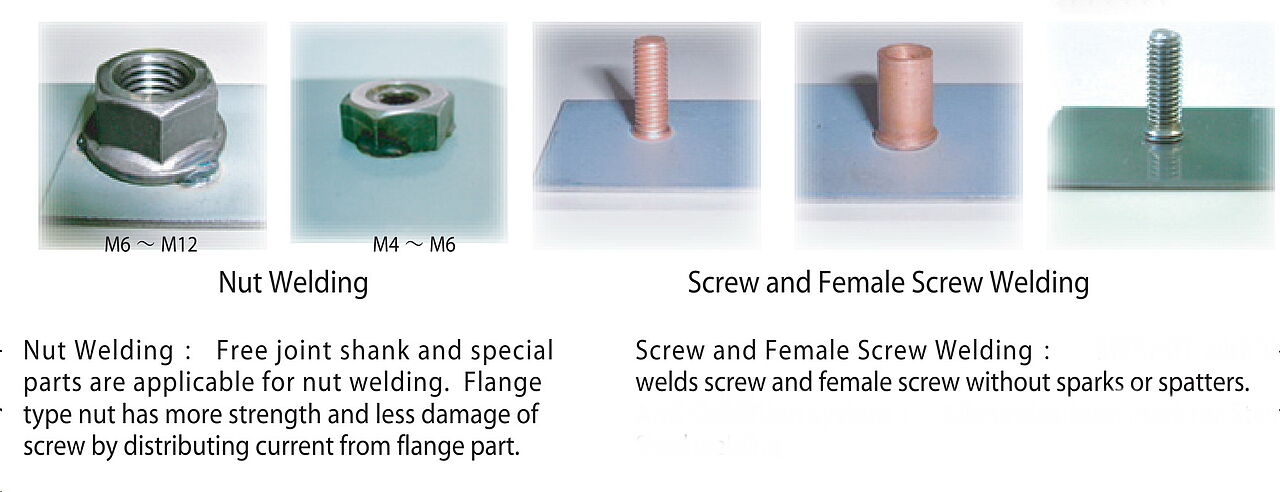

Drastically improves the weld quality of inserts and butt welds - special for clean stud welding

Spot Welding machine

Less labor for welding large parts

The operator can manually move the welding unit quickly over the entire working area. It makes the welding of large parts much easier because there is no need to move them during operation.

Refined welding effect

The wide contact surface at which the current is distributed allows achieving good visual quality that is unfeasible with standard spot welding machines. It minimizes time for cleaning and refinement; the product is ready for further assembly and painting after welding.

Sturdy reinforced steel construction

The sturdy reinforced steel construction can withstand significant mechanical and electromagnetic load.

Automated pneumatic cylinder pressure control

The proportional valve enables automatic pressure control in the pneumatic cylinder when the value of the compression force on the electrode changes, which reduces the number of waste.

The first important feature of the new version of the PROFISPOT-CNC® CNC pressure welding machines is the large working bench, where a thick 10 to 30mm flat copper plate acts as counter-electrode and dissipate the heat perfectly.

This makes easy to locate onto the bench either large pieces, like doors, or small ones, like shelves, which can also be in several units.

The second main feature is the solid “flag type” welding head which can run at high speed along X and Y axis, releasing a welding force up to 1800 daN.

Standard dimensions of the table are 1200x2400mm, but larger can be supplied on demand, with the possibility to split it into two or more areas (working/loading-unloading), to speed up the productivity.

This type of compact structure makes possible reaching the highest speed on its market sector, targeting 40 real welding spots per minute.

The PROFISPOT-CNC® CNC pressure welding machines are equipped with last generation of Medium Frequency package with all related advantages in quality and energy saving.

Programming is made simpler, faster and more intuitive by using the latest easy-friendly technology.