Resistance welders in different versions

Depending on the power and application area, we build our welding machines for you as floor or table-top welding machines. For the drive, pneumatic cylinders and servomotor systems through magnetic linear actuators of all conventional technical standards are possible. Furthermore you can choose between alternating, medium frequency and capacitor discharge technology. The various types of our spot, projection and roller-seam welding machines differ in the nominal power, electrode force, electrode stroke and available welding window. Our experts will determine which variant best meets your requirements. Let’s talk about your concrete project - we would be glad to advise you and configure your individual welding machine for you.

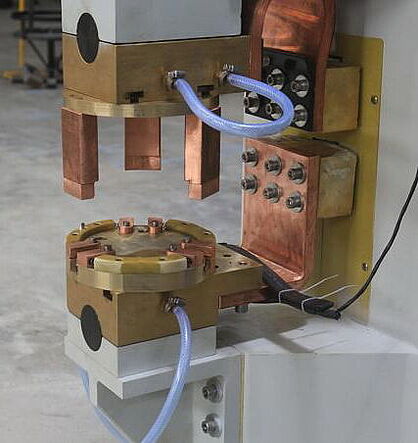

PROFISPOT® Pressure Welding Machines

Select your machine

PROFISPOT® - Spot Welding Machines

Efficient spot welding machine for joining sheet metals

Projection Welding Machines

For quick projection welding joints

PROFISPOT-T® -Table Spot welding Machines

Invisible spot welding results

PROFISPOT-CNC® - CNC pressure welding Machines

Punch press type CNC pressure welding machine

Nut Welding Machines

Efficient spot welding machine for safe joints of nuts to base

Benefits in an overview:

Individually configurable

We will configure the perfect device for your welding challenge. To accomplish that our technicians in the welding lab step into action for you: they perform trials in the welding lab on the materials you have supplied, create and test the welding samples and determine the main welding parameters. That information is used to create your plant quickly and cost-effectively.Robust and tough

High-grade components, excellent craftsmanship and the massive, torsion-free basic body of our spot welding machines guarantee their long durability and high-quality weld connections. The are often used for many decades and permanently work with absolutely reliability.

Shorter delivery times, good price-performance ratio

A comprehensive modular system, the production of individual components in our own factory and highly-qualified employees with many years of experience ensure that we can supply high-quality resistance spot welding equipment quickly at attractive prices.

Meet the safety regulations

All spot welding machines that leave our factory meet the legal safety regulations and comply with the high requirements of Performance Level D.

Our welding machines can handle all following resistance welding processes:

Depending on the shape of the workpieces and the form of the electrodes, resistance welding processes can be classified into several variants as described below:

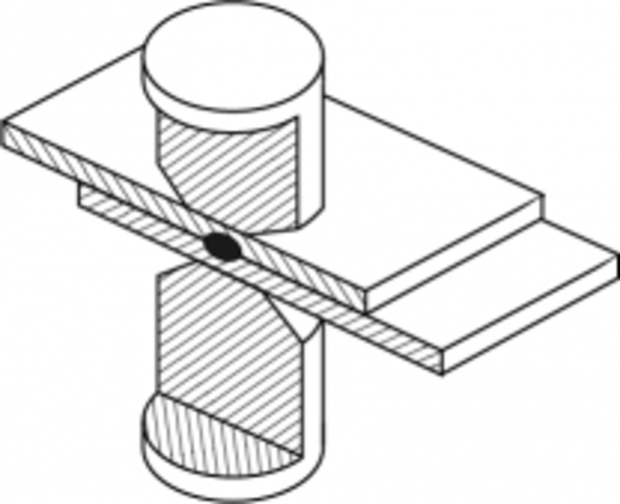

Resistance Spot Welding

Spot welding is a resistance welding process for joining metal sheets by directly applying opposing forces with electrodes with pointed tips.

The current and the heat generation are localized by the form of the electrodes. The weld nugget size is usually defined by the electrode tip contact area.

Spot welding is the predominant joining process in automotive industry for assembling the automobile bodies and large components. It is also widely used for manufacturing of furniture and domestic equipment etc.

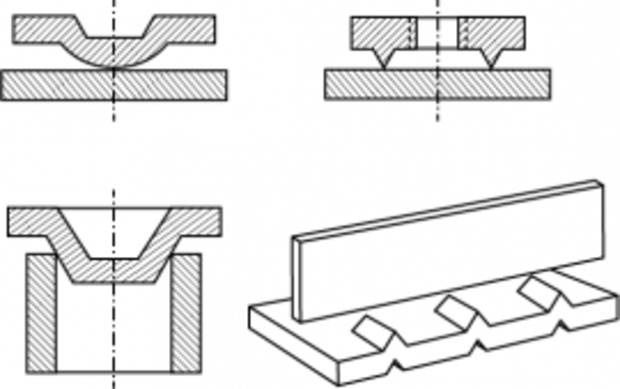

Resistance Projection Welding

Projection welding is a resistance welding process for joining metal components or sheets with embossments by directly applying opposing forces with electrodes specially designed to fit the shapes of the workpieces. The current and the heat generation are localized by the shape of the workpieces either with their natural shape or with specially designed projection. Large deformation or collapse will occur in the projection part of the workpieces implying high process/machine dynamics.

Projection welding is widely used in electrical, electronics, automotive and construction industries, and manufacturing of sensors, valves and pumps etc.

Resistance seam welding

Seam welding is a resistance welding process for joining metal sheets in continuous, often leak tight, seam joints by directly applying opposing forces with electrodes consisting of rotary wheels. The current and the heat generation are localized by the peripheral shapes of the electrode wheels.

Seam welding is mostly applied in manufacturing of containers, radiators and heat exchangers etc.

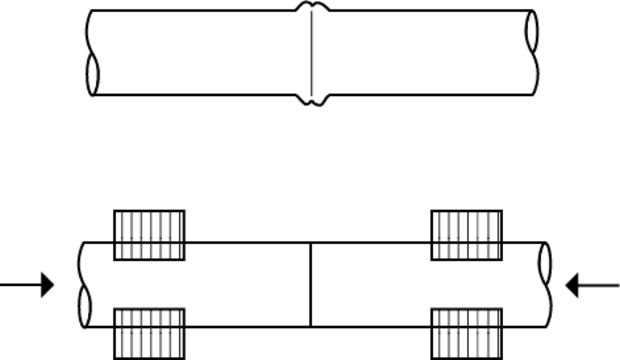

Resistance Butt-Welding

Butt welding is a resistance welding process for joining thick metal plates or bars at the ends by directly applying opposing forces with electrodes clamping the workpieces. A forging operation is applied after the workpieces are heated up. Often no melt occurs, thus a solid state weld can be obtained.

Butt welding is applied in manufacturing of wheel rims, wire joints and railway track joints etc.

More pressure welding processes our machines can handle

Single-Sided (One-Sided) Resistance Welding

Is a special resistance welding process where the weld is made with only one electrode accessing from one side to the weld zone with or without a backing plate from the other side. Low weld force is usually used, which limits the single-sided (one-sided) spot welding to joining of relatively thin sheets. It may be useful for welding components with limitation of electrode access from both sides.

Resistance Weld Bonding

Is a combined joining process with adhesive bonding and resistance welding. The adhesive is applied to the faying surfaces of sheets to be welded, and subsequently resistance spot weld is made through the sheets before curing of the adhesive. The joint can have good strength from the spot welding and good stiffness from the adhesive bonding.

Cross Wire Welding

Is a resistance welding process for joining bars or wires in cross joints by directly applying opposing forces with usually flat electrodes. The current and the heat generation are localized at the contact points of the crossed bars or wires. Cross wire welding is widely used in construction and electrical industry as well as for manufacturing of metal wire nets and shopping trolleys etc.

Indirect Welding

Is a special resistance welding process where a single weld is made with one electrode directly connecting to the weld zone, while the other electrode is offset at a distance, but still conducts the current along the workpiece.

Series Welding

Is a special resistance welding process where two welds are made at the same time with two electrodes offset at a distance but still conducting the current along the workpieces between the two welds.

Micro Resistance Welding

Refers to the resistance welding processes for joining micro or miniaturized components, which in principle can be any of the above mentioned process variants but in a micro scale.