PROFISPOT-F ®

Nut Stud & Bolt Feeder Systems

Offering high performance and accuracy in resistance welding, PROFISPOT-F ®'s automatic Nut Feeders & Stud Bolt Feeders allow for feeding both single or double fastners. The High Performance Nut Feeder can weld up to 60 nuts per minute and the Automatic Stud Feeder can also weld up to 60 bolts per minute and has the added advantage of low noise.

PROFISPOT ® supply a full range of stud feeders for feeding single or double studs. PROFISPOT-F ® carries a varied range of ISO cap electrodes with different nose configurations in three different types of materials.

- The machine is perfect for cap nuts welding; size range M4~M16.

- The machine loads nuts and caps onto the special welding unit automatically.

- Automatic welding and discharging.

- Better productivity: Up to 40-60 pieces per minute.

Nut feeders

- Automatic nut feeding

- High positioning accuracy

- Top cover for low noise and high protection

- Several PLC options

- Single or double feeding

- Manual or automatic (In Line) cycle

Bolt feeders

- Automatic bolt feeding

- High positioning accuracy

- Top cover for low noise and high protection

- Several PLC options

- Single or double feeding

- Manual or automatic (In Line) cycle

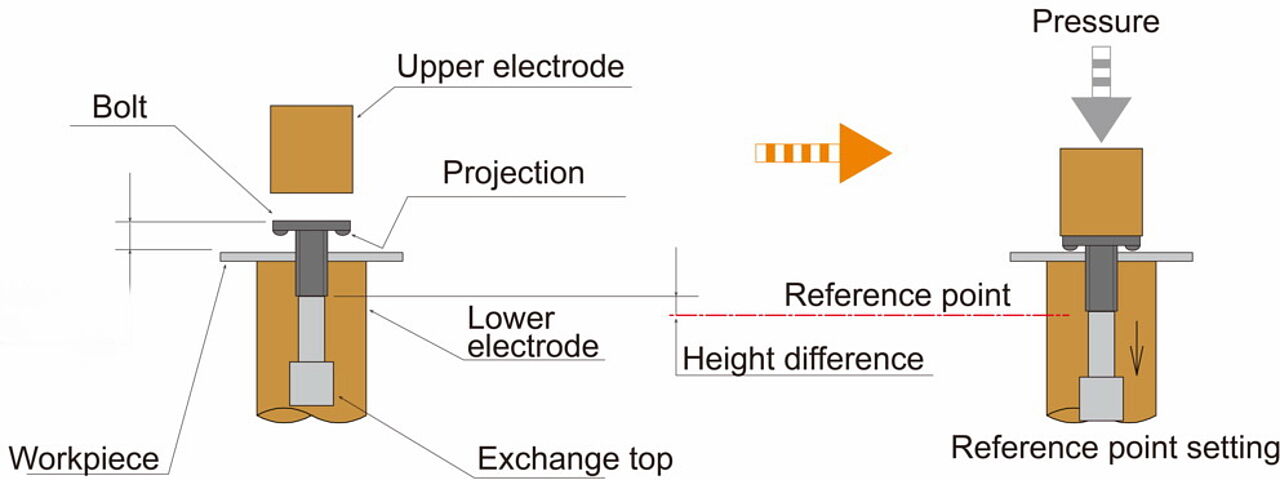

Profispot-F projection welding machine

Profispot-F projection welding machine is a cap nuts welding machine that matches the processing demands from automobile and motorcycle industry. The cap nut welding machine can weld cap nuts from M4 to M20 size, and the automatic loading mechanism can load nuts and caps to the special welding tools. Moreover, the cap nut welding machine can do automatic welding and discharging, with high productivity of 60 pieces per minute.

Energy Efficient

Three Phase Inverter DC Output Current Solution

The three phase balanced input with constant DC output saves 70% energy consumption compared to standard Single Phase AC machines.

High Return on Investment

Low Energy Cost and Efficient Production

With the 70% energy cost reduction, it could save up to an annual expanse of € 20.000,- compared with AC machines. Lowly connected load requirement.

High Production Efficiency

Preloading System

Onsite operators can load the nuts, studs or bolts onto the preloading system without stopping the machine. The preloading system helps the auto feeding into the welding station, enhancing the safety and efficiency of the grating welding machine

Save Labor & Increase Safety

Cross Bar Auto Loading System

The pneumatic auto loader feeds and positions the nuts, studs or bolts perfectly onto the welding position accurately before welding.

Stable & Excellent Welding Quality

High current density with stable pressure from the heat-treated cast iron head (supported by four heavy duty steel columns) results in high penetration and excellent welding quality.

EPW: Euro Pressure Welder for Projection Welding

Pneumatic Projection Pressure Welding Machines - Build for Europe - Standard Dimensions

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIMENSIONS | |||||||||||||

| Width | mm | 550 | 550 | 550 | 480 | 480 | 480 | 480 | 780 | 780 | 780 | 800 | 950 |

| Depth | mm | 700 | 700 | 700 | 900 | 900 | 900 | 900 | 1250 | 1250 | 1250 | 1300 | 1320 |

| Height | mm | 1120 | 1120 | 1120 | 1500 | 1600 | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | |

| Weight | kg | 180 | 180 | 180 | 220 | 280 | 310 | 350 | 400 | 500 | 700 | 1000 | 1500 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| MECHANIC SPECIFICATIONS | |||||||||||||

| Maximum Pressure force | kgf | 200 | 200 | 200 | 300 | 300 | 350 | 500 | 1000 | 1000 | 1300 | 1500 | 2000 |

| Electrode Stroke | mm | 50 | 50 | 50 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | |

| Closure | mm | 65-115 | 65-115 | 65-115 | 65-115 | 145-225 | 145-225 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 |

| Platform Distance ** | mm | 250 | 250 | 250 | 260 | 260 | 260 | 260 | 260 | ||||

| Cooling Water debit | l/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| ELECTRIC SPECIFICATIONS | |||||||||||||

| Input Voltage | V | 220/1 | 220/1 | 220/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 |

| Input Power | KVA | 10 | 10 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 150 | 200 | 300 |

| Output Current | A | 5000 | 6000 | 8000 | 10000 | 12000 | 16000 | 19500 | 24000 | 34000 | 40000 | 50000 | 75000 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| AVAILABLE CONTROLLER | |||||||||||||

| CD : Condensator Discharge Controller | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD |

| AC : Alternative Current Discharge Controller | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC |

| MFDC : Medium Frequency (1000Hz) Direct Current driven Alternate Current Discharge Controller | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC |