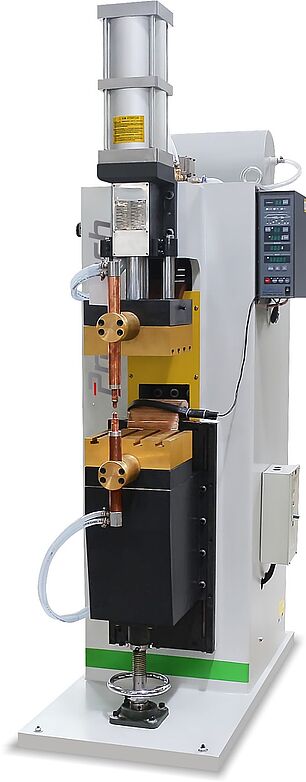

Profimach Combined Projection welding machines - Combinetd Spot Welding Machines

Our Combined Projection/Spot-Welding machines are designed for applications that require more current and more force than standard equipment is intended. Our heavy-duty Spot-Welders - Projection welders use a very sturdy C-frame and can be considered as one of the most rigid on the market today.

Our Heavy-Duty Projection Type Resistance Welders are widely used by the metalworking industries today because of its extreme versatility. This general-purpose machine represents a new high achievement in welder design and engineering and embodies advantages which afford the greatest performance. Its modern design has incorporated ruggedness, accuracy, and reliable uninterrupted performance – all of which are of utmost importance to high production rate.

The main frame is high quality welded steel construction styled for trim appearance and functional design. The slim design requires a minimum of floor space. The upper arm extension is built integrally with the frame. The removable rear cover permits ready access to the frame interior for inspection and maintenance.

All our machines are fully digital controlled with the latest microprocessed power controller.

Our welding machines can be delivered equipped with one of following controllers and power sources:

- Digital Capacity Discharge (CD) welding controller

- Digital Alternateing Current (AC) welding controller

- Digital Medium Frequency inverted Direct Current (MFDC) welding controller

Depending process, workpiece, budget and workload, the perfect choice for your job is always available.

EPW: Euro Pressure Welder combined Spot and Pressure Welding

Pneumatic Pressure Welding Machines - Build for Europe - Standard Dimensions

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIMENSIONS | |||||||||||||

| Width | mm | 550 | 550 | 550 | 480 | 480 | 480 | 480 | 780 | 780 | 780 | 800 | 950 |

| Depth | mm | 700 | 700 | 700 | 900 | 900 | 900 | 900 | 1250 | 1250 | 1250 | 1300 | 1320 |

| Height | mm | 1120 | 1120 | 1120 | 1500 | 1600 | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | |

| Weight | kg | 180 | 180 | 180 | 220 | 280 | 310 | 350 | 400 | 500 | 700 | 1000 | 1500 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| MECHANIC SPECIFICATIONS | |||||||||||||

| Maximum Pressure force | kgf | 200 | 200 | 200 | 300 | 300 | 350 | 500 | 1000 | 1000 | 1300 | 1500 | 2000 |

| Electrode Stroke | mm | 50 | 50 | 50 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | |

| Closure | mm | 65-115 | 65-115 | 65-115 | 65-115 | 145-225 | 145-225 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 |

| Platform Distance ** | mm | 250 | 250 | 250 | 260 | 260 | 260 | 260 | 260 | ||||

| Electrode Distance ** | mm | 145-165 | 145-165 | 145-165 | 320-420 | 320-420 | 320-420 | 490-540 | 490-540 | 490-540 | 490-540 | ||

| Cooling Water debit | l/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| ELECTRIC SPECIFICATIONS | |||||||||||||

| Input Voltage | V | 220/1 | 220/1 | 220/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 |

| Input Power | KVA | 10 | 10 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 150 | 200 | 300 |

| Output Current | A | 5000 | 6000 | 8000 | 10000 | 12000 | 16000 | 19500 | 24000 | 34000 | 40000 | 50000 | 75000 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| AVAILABLE CONTROLLER | |||||||||||||

| CD : Condensator Discharge Controller | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD |

| AC : Alternative Current Discharge Controller | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC |

| MFDC : Medium Frequency (1000Hz) Direct Current driven Alternate Current Discharge Controller | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC |