Spot welding machine for welding sinks into counters

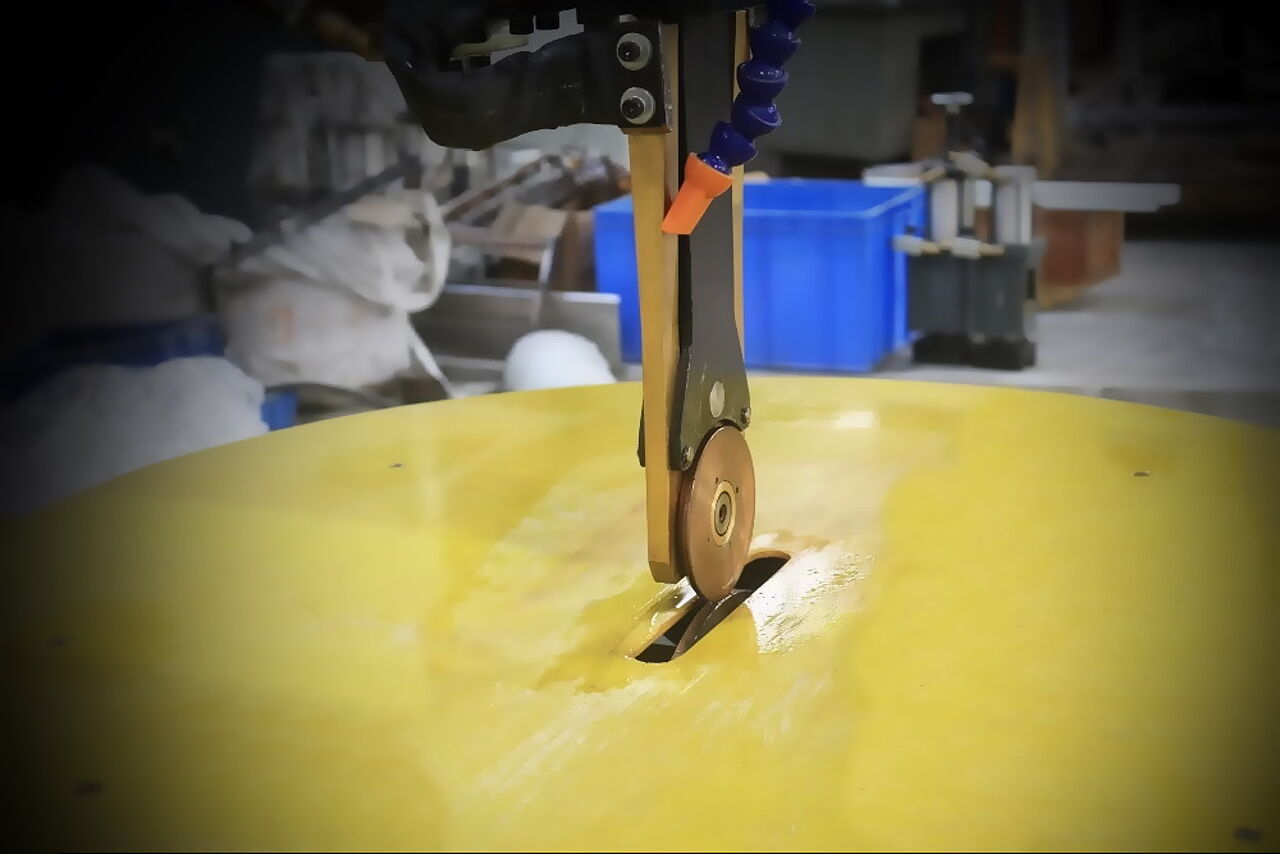

Specially designed manual spot welding machine for waterproof joining of sink-basin into a custom designed countertop.

Our Manual Sink welding machine offers fast, easy and cost-effective, watertight welding of inox (stainless) sinks and drainers into inox counters and worktops. It is suitable for welding stainless steel sinks, bowls, fryers, basins of all shapes and sizes into kitchen countertops, worktops and drainers to use in gastronomy (HORECA) and medicine.

Choosing spot welding over gas Tungsten arc welding (TIG) or seam welding, enables our customers more flexibility in designing and production of their worktops, since “Profispot Sink Welder” offers higher speeds, higher quality and less deformation than Tungsten arc welding (TIG). Although spot welding is slower than seam welding, our machine does not require any special copper counter electrodes as seam welding does. The result is a seam-like weld, which is waterproof, but does not cause any deformation in the sheet metal.

We offer innovative guiding tables, placed under the countertop, for easy handling and to support the weight of larger countertops, so that only one unqualified worker is needed. The worker does not need to rotate the countertop or program the machine, because the machine follows the shape of the sink-bowl automatically. Therefore any shape of the sink-bowl can be welded-in without any machine setting up or CNC programming.

Advantages of our sink seam welding machine

- Time savings: welding finished in 80-120 seconds per average sized sink.

- Superb welding quality. Product without any deformation and bending in the sheet metal.

- Quick investment turnover.

- Simple operation.

- No qualified work force needed (only one worker needed).

- Watertight welding.

- Rotation of the countertop is not needed.

- No limits for the counter dimensions.

- No need for CNC-PLC programming.

- Automatic guidance according to the basin-sink shape.

- Cooling water can be recycled.

- Patented technology.

Impermeable seams guaranteed; during roller-seam welding

The most important thing during roller-seam welding is that the seam is absolutely impermeable. And that is exactly what our high-performance machines guarantee. Because, we always produce for you at the highest level of quality and according to your requirements. And we accomplish that on short notice and at attractive prices. How is that possible? Simple: We manufacture your roller-seam welding machine based on the modular system that includes a large number of components and a comprehensive accessory range. We manufacture nearly all individual parts and above all the transformer, the core-component of every welding machine, ourselves, which ensures that they meet the highest demands and are always in stock. The exact appearance of your machine depends on your individual needs. We will gladly also take concrete specifications, for instance regarding pneumatics, controller or color, into account. After all, your requirements for roller-seam welding is what drives us.