Projection Welding Machines

A modern car body contains some 300 welded and punched fasteners, such as bolts, nuts, and studs. The quality of the attachment of these fasteners to the stamped body components is critical for the final product's safety and reliability. Crucial components such as the front and rear axles are mounted to such fasteners, the seat belts and steering column are anchored to them, and they provide grounding for electrical wires.1

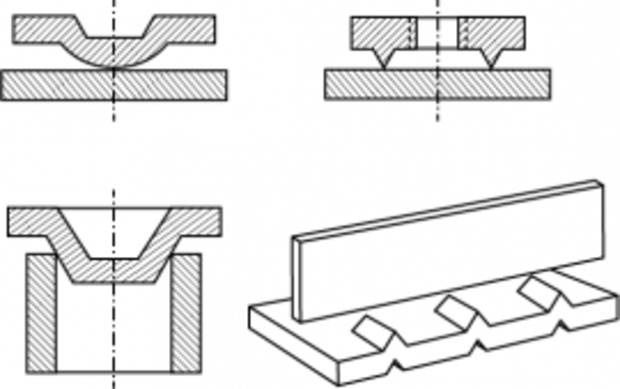

Projection welding is the most common method for nut and M- or T-thread bolt welding. These nuts and bolts are provided with annular projections or three to four separate projections, depending on the application. With an annular projection and a plastic insert, some nut types can achieve a watertight joint. The annular projection also is preferable for attachments subjected to fatigue stress and high loads. Compared to fasteners with separate projections, the annular projection offers fewer crack initiation points.

The Projection Welding Process

Resistance fastener welding, generally called projection welding, is similar to resistance spot welding. However, in the spot welding process, the size of the contact surface of the electrode cap tip determines the current flow, whereas in projection welding, the current flow is constricted to the embossed or machined projection. Both AC and DC power sources are suitable for fastener welding. The heat balance for projection welding is affected by the following factors:2

- Projection design and location

- Thickness of the sheet to which the fastener is attached

- Thermal and electrical conductivities of the metals being welded

- Heating rate

- Electrode alloy type

Projection welding of a weld nut or weld bolt involves three phases. In the first phase, the projection is in contact with the mating sheet. Then the current starts to heat the projection to welding temperature. The electrode force then causes the heated projection to collapse rapidly, and fusion takes place.

The current for projection welding is generally less than that required to produce correspondent spot welds. The projection will heat rapidly, and excessive current will melt it and result in expulsion. However, the current must be at least high enough to create fusion before the projection has completely collapsed.

A short welding time might be desirable from a production standpoint, but it will require correspondingly higher amperage. Therefore, it is important to optimize welding parameters to prevent overheating and metal expulsion. In some cases, such as when welding fasteners to high-strength steels (HSS), impulse welding may be advantageous to control the heating rate. This also is helpful for thick-sheet projection welding and when welding metals with low thermal conductivity.

The electrode force should be adequate to flatten the projections completely when they reach welding temperature and to bring the fastener in contact with the sheet metal part. Excessive force will prematurely collapse the projections, and the weld will have an incomplete fusion in the center. The welding machine must be able to follow the movement of the electrodes as the projections collapse. Slow follow-up will result in metal expulsion before the parts have been brought together.

EPW: Euro Pressure Welder for Projection Welding

Pneumatic Projection Pressure Welding Machines - Build for Europe - Standard Dimensions

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DIMENSIONS | |||||||||||||

| Width | mm | 550 | 550 | 550 | 480 | 480 | 480 | 480 | 780 | 780 | 780 | 800 | 950 |

| Depth | mm | 700 | 700 | 700 | 900 | 900 | 900 | 900 | 1250 | 1250 | 1250 | 1300 | 1320 |

| Height | mm | 1120 | 1120 | 1120 | 1500 | 1600 | 1600 | 1600 | 1800 | 1800 | 1800 | 1800 | |

| Weight | kg | 180 | 180 | 180 | 220 | 280 | 310 | 350 | 400 | 500 | 700 | 1000 | 1500 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| MECHANIC SPECIFICATIONS | |||||||||||||

| Maximum Pressure force | kgf | 200 | 200 | 200 | 300 | 300 | 350 | 500 | 1000 | 1000 | 1300 | 1500 | 2000 |

| Electrode Stroke | mm | 50 | 50 | 50 | 80 | 80 | 80 | 80 | 100 | 100 | 100 | 100 | |

| Closure | mm | 65-115 | 65-115 | 65-115 | 65-115 | 145-225 | 145-225 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 | 130-230 |

| Platform Distance ** | mm | 250 | 250 | 250 | 260 | 260 | 260 | 260 | 260 | ||||

| Cooling Water debit | l/min | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| ELECTRIC SPECIFICATIONS | |||||||||||||

| Input Voltage | V | 220/1 | 220/1 | 220/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 | 380/1 |

| Input Power | KVA | 10 | 10 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 150 | 200 | 300 |

| Output Current | A | 5000 | 6000 | 8000 | 10000 | 12000 | 16000 | 19500 | 24000 | 34000 | 40000 | 50000 | 75000 |

| MODEL | EPW | 3 | 5 | 10 | 16 | 25 | 35 | 50 | 75 | 100 | 160 | 200 | 300 |

| AVAILABLE CONTROLLER | |||||||||||||

| CD : Condensator Discharge Controller | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD | CD |

| AC : Alternative Current Discharge Controller | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC | AC |

| MFDC : Medium Frequency (1000Hz) Direct Current driven Alternate Current Discharge Controller | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC | MFDC |

PROFISPOT-F ® Offering automatic nut and stud loading devices: Click here to visit

PROFISPOT-F ®'s automatic Nut Feeders & Stud Bolt Feeders allow for feeding both single or double fasteners.

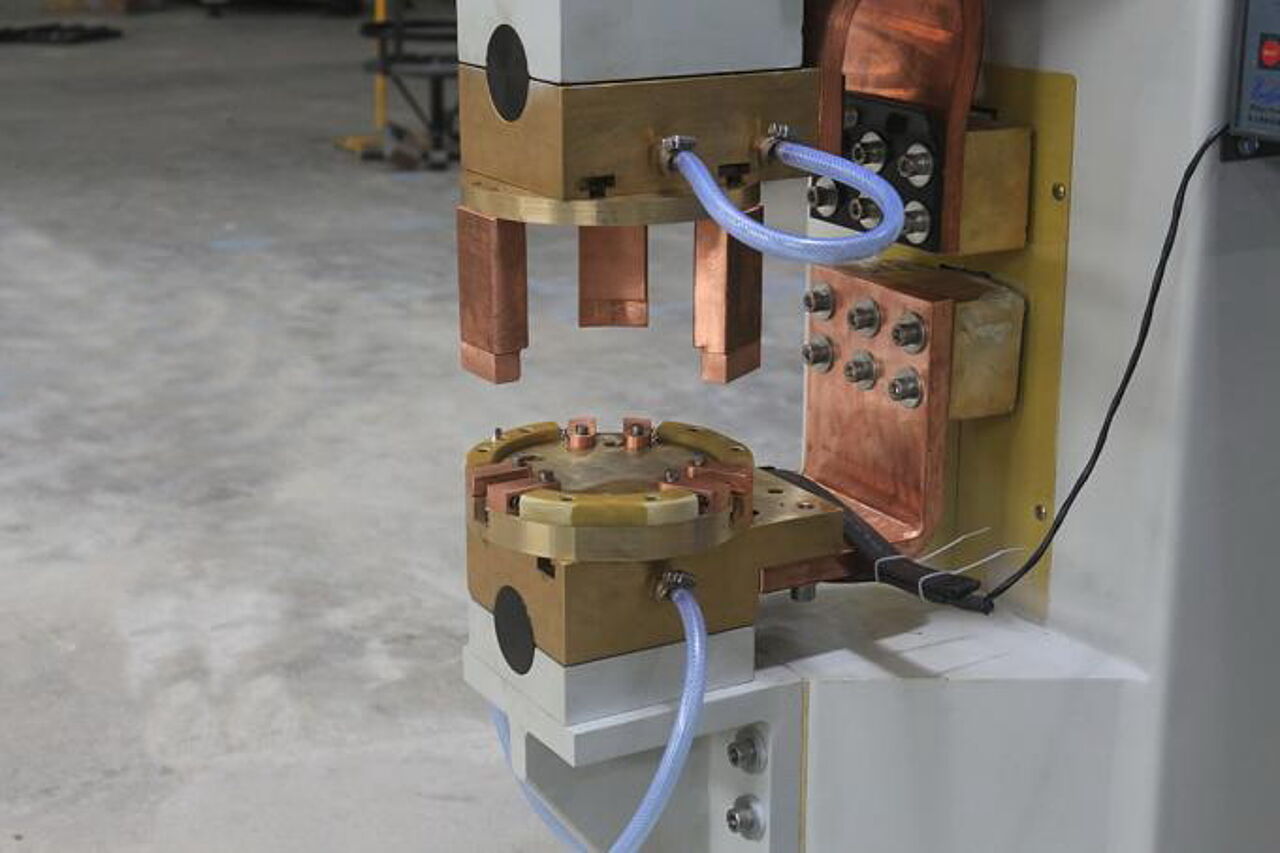

Profispot-F projection welding machine is a cap nuts welding machine that matches the processing demands from automobile and motorcycle industry. The cap nut welding machine can weld cap nuts from M4 to M20 size, and the automatic loading mechanism can load nuts and caps to the special welding tools. Moreover, the cap nut welding machine can do automatic welding and discharging, with high productivity of 60 pieces per minute.

Energy Efficient

Three Phase Inverter DC Output Current Solution

The three phase balanced input with constant DC output saves 70% energy consumption compared to standard Single Phase AC machines.

High Return on Investment

Low Energy Cost and Efficient Production

With the 70% energy cost reduction, it could save up to an annual expanse of € 20.000,- compared with AC machines. Lowly connected load requirement.

High Production Efficiency

Preloading System

Onsite operators can load the nuts, studs or bolts onto the preloading system without stopping the machine. The preloading system helps the auto feeding into the welding station, enhancing the safety and efficiency of the grating welding machine

Save Labor & Increase Safety

Cross Bar Auto Loading System

The pneumatic auto loader feeds and positions the nuts, studs or bolts perfectly onto the welding position accurately before welding.

Stable & Excellent Welding Quality

High current density with stable pressure from the heat-treated cast iron head (supported by four heavy duty steel columns) results in high penetration and excellent welding quality.