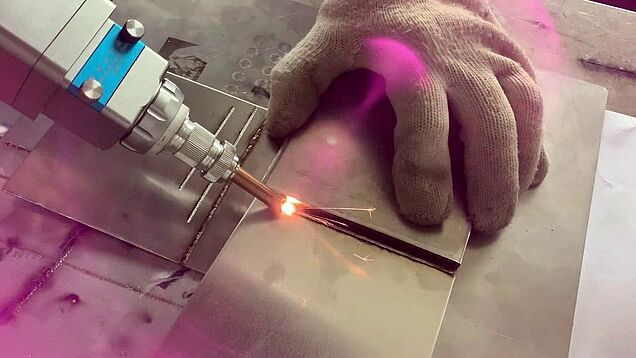

Lasermach WOBBLE: Handheld fiber laser welding machine

FAST, economical and safe hand welding with fiber laser beam

Handheld Fiber Laser welding offers a fast, economical and contact-free alternative for welding a wide variety of metals in virtually every industry.

Whether you require high processing speed, complex weld geometries or multi-layer joints, Wobble-3 provides unique solutions for a diverse range of welding applications.

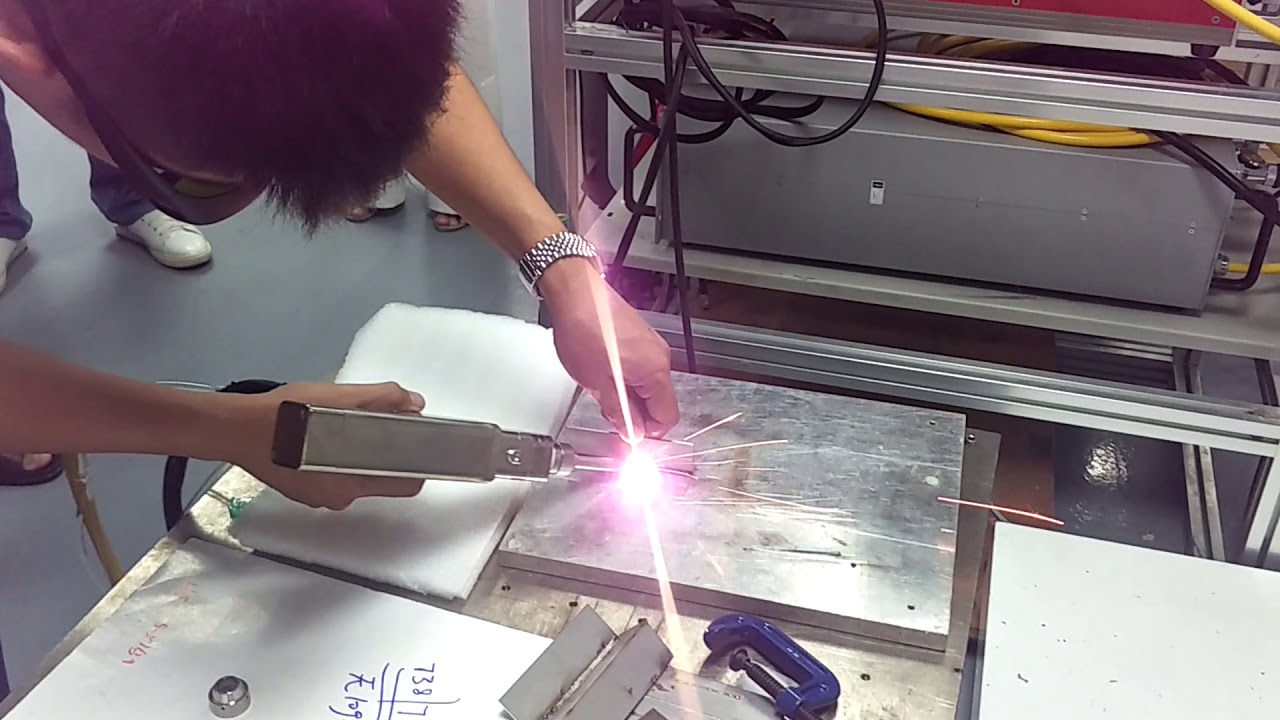

High Power Laser Welding of Metals

Fiber laser 0.5 kW 1.0kW 1.5kW 2.0kW for handheld welding

Fiber lasers in the power range of 1000 W to 3000 W can weld heavier metals connections at high speeds.

Applications can be as diverse as stainless steel sheets for kitchen tops, galvanized steel backplates for flat screen LCD TV’s, sheet steel for stators in electric motors, structural parts such as turbocharger waste gates, stainless steel bellows, copper wires, tabs for batteries, etc.

Thicknesses of up to 5 mm can be welded and speeds of up to 50 cm/second can be achieved.

Fiber lasers in this power range are increasingly replacing other welding processes such as Resistance Welding (spot welding), TIG welding, MIG welding, Electron beam welding, etc.

With lasers at these power levels, the weld speed is typically only limited to the speed of moving the system or the parts and feeding the parts to and from the system. In the coming years, the power of these lasers is expected to increase by 20% - 30% year on year and even more traditional welding processes will be replaced by laser welding.

Click Here to visit our Fiber laser Welding Website

Wobble-3 and Wobble-3Plus

Best Handheld fiber laser machine in the market here available

Wobble welding technology allows your team to skip the filler material while achieving a quality welding seam.

Laser welding uses high-energy laser pulses to locally heat the material in a small area.

The energy of the laser radiation diffuses into the material through heat conduction,

and the material is melted to form a specific molten pool.

It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts,

which can realize spot welding, butt welding, stack welding, sealing welding, etc.

The welding speed is fast, no treatment is needed after welding, and the quality of the weld is high.

The weld can be precisely controlled, small focus spot, high positioning accuracy, easy to automate.